Industrial air compressor and compressed air energy monitoring equipment and technology.

Advanced hardware, software and cloud computing solutions that enable compressed air systems to be quickly and easily monitored and audited online all the time.

FEATURES

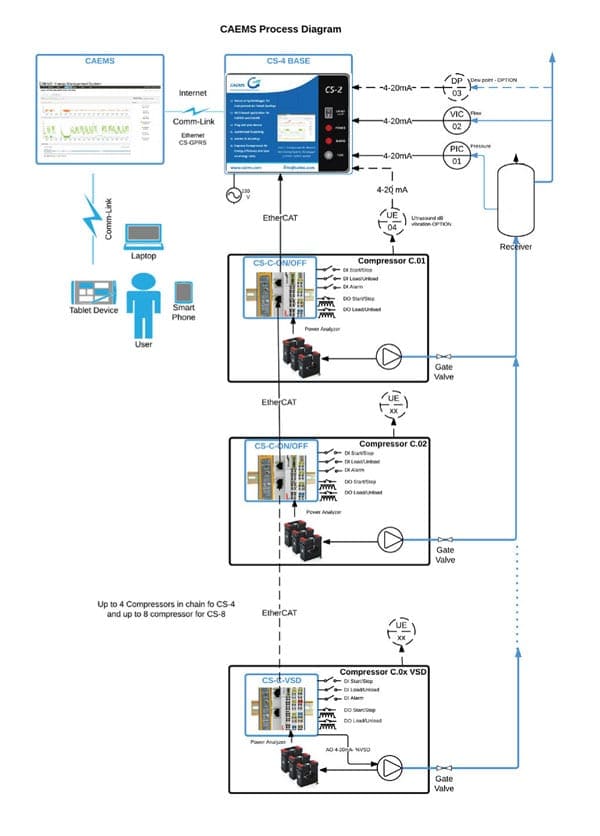

- 3 in 1 – Compressed Air Remote Monitoring System.

- Datalogger and PLC Control System for detailed analysis.

- Plug and play device with user-friendly interface.

- WEB-based application.

- Auto-generated alarms & warnings with email or SMS notification including details of malfunction.

- Detailed analysis and report on demand, including potential savings and efficiency comparison.

- Possibility of expanding and remote software upgrading.

- Multiple data export options (CSV, XML).

- Multiple access for end-users and experienced CA partners.

BENEFITS

Instant access, anywhere, anytime – Manage your compressed air system(s) remotely and receive instant notification when parameters slip and the system isn’t performing at best practice levels.

Reduce energy waste, improve the quality of compressed air to your plant, reduce downtime and minimise compressed air system running costs through monitoring and optimisation.

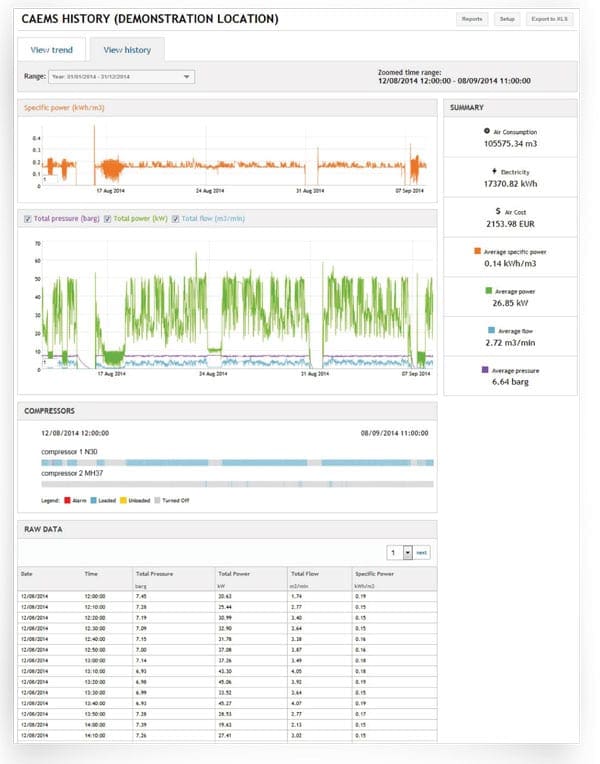

Real-time continuous monitoring of :

- Plant Compressed Air Consumption

- Energy Usage

- System Pressure

- Compressed Air Quality

- Overall System Efficiency

- Non-Productive Demand

- Compressor Performance

- Dryer Performance

- Filter Performance

Monthly analysis and reporting by Compressed Air System expert :

- Trend analysis to ensure the compressed air system is performing optimally

- Recommendations and optimisation initiatives to reduce energy consumption and improve reliability

- Modelling with ROI data for potential optimisation projects

- Dedicated compressed air expert for your site(s)

Real time, customisable, SMS or email alarming and notification of :

- Excess Plant Compressed Air Consumption

- Excess Energy Usage

- Low Pressure Events

- Leakages & Artificial Demand

- Overall System Efficiency Levels

- Compressed Air Purity Issues – Excess Moisture, Oil, Particulate

- Excessive Pressure Drop – Blocked Filters, Frozen Dryers etc

- Compressor Performance Issues – Reduced FAD, Low Pressure etc

- Dryer Performance Issues – High Dew Point, Blocked Drains etc

- Filter Performance Issues – Element Deterioration

CONTROLLING AND MONITORING

- Specific energy consumption.

- Monitoring & targeting.

- Target deviation (product & energy production).

- Display of current process data (pressure, flow, power) every 5s/5min.

- Archive of process data (1h average).

- View of active alarms, settings and alarm archive.

- Energy quality –OPTION (standard EN50160).

- Frequency deviations.

- Voltage deviations, dips, interruptions, unbalances.

WHAT TO EXPECT

- Specific energy consumption.

- Monitoring & targeting.

- Target deviation (product & energy production).

- Display of current process data (pressure, flow, power) every 5s/5min.

- Archive of process data (1h average).

- View of active alarms, settings and alarm archive.

- Energy quality –OPTION (standard EN50160).

- Frequency deviations.

- Voltage deviations, dips, interruptions, unbalances.

More information

To discuss how our compressed air energy management systems can assist in delivering real-time analytics and identify potential issues before they happen, contact our compressed air specialists. We can demonstrate how you can cost-effectively reduce energy wastage, increase productivity and significantly reduce operating costs.

We are Sydney’s leading compressed air specialists

Compressed Air Technology are specialist consultants and contractors for the compressed air industry. Working with industrial compressed air operators to maximise efficiency, reliability and productivity. We design, supply, install, monitor and certify compressed air systems for a wide range of industries Australia wide.

Our independence is the key to our success

Huge increases in the cost of energy has seen the company start to focus on energy management. We are now regularly called upon in a consulting capacity to design compressed air systems that are efficient as well as reliable and safe. Our independence is key to our success, we are not encumbered by the constraints of a typical compressor dealer, we design each system with an open mind and scour the market for equipment that best suits our clients needs.

Helpful links : Compressed air system design | New air compressor installations | Compressed air system sales

We use specialist compressed air equipment

The company has invested heavily in specialist measuring, monitoring and testing equipment, along with the training of personnel to operate and understand measurement and monitoring methods for compressed air and gas systems. Our whole approach sets Compressed Air Technology apart from the crowd, we believe in what we do, are passionate about compressed air and strive to build long lasting, mutually beneficial relationships with a wide range of clients across a variety of sectors.

Helpful links : Air compressor services | Compressed air evaluation & audits | Compressed air leak detection | Compressed air quality testing