Buying a new air compressor? Do you really understand the compressed air requirements of your plant? Do you know how much air your equipment consumes and at what pressure? Are you aware that the single biggest cost associated with owning and operating an air compressor system will be the electricity costs required to run it?

Over a typical 10 year air compressor life cycle, the cost of energy will account for around 75%-80% of total costs, dwarfing the initial costs associated with equipment purchase, installation and maintenance.

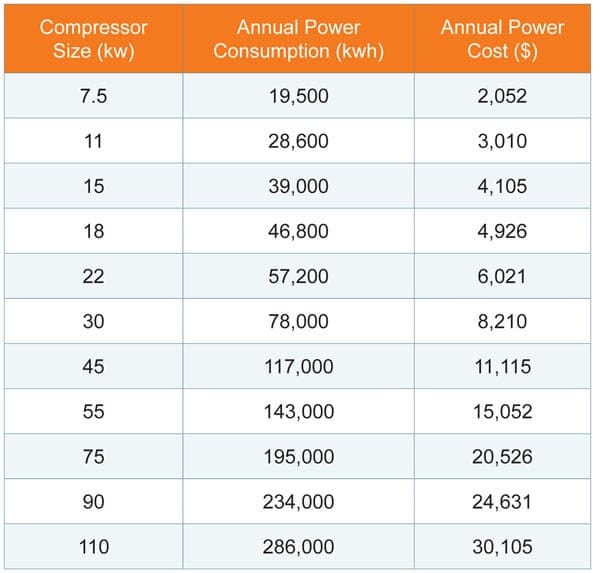

Consider the table below, showing electricity costs to run an air compressor five days a week for 10 hours per day.

Air Compressor Expenditure

The chart below outlines the typical electricity expenditure associated with running an industrial air compressor (excluding maintenance).

Calculations based on compressor running fully loaded 10 hours per day, 5 days per week (2600hrs p/a) and a blended power rate of $0.10/kWh

Further reading :

Independent air compressor sales advice

Before you contact the usual air compressor dealers, consider getting your current or proposed new system properly appraised, so that you can be sure you are buying what you actually need as opposed to what you are being sold.

At Compressed Air Technology, we make the effort to actually measure and monitor your system BEFORE you proceed with a high value purchase, ensuring the lifetime ownership costs are kept to a minimum.

As an independent operator, not tied to any particular brand, we have access to a huge range of premium quality equipment that is selected to ensure compressed air is supplied to your plant at the correct volume, pressure and quality, with a heavy focus on reliability.

We also supply a range of piping systems including aluminium, copper, stainless steel, HDPE and many more

Contact us for an obligation free compressed air system assessment on 1300 663 113.

Call 1300 663 113 Email Us Online Enquiry »

We are Sydney’s leading compressed air specialists

Compressed Air Technology are proudly client focused, specialist compressed air professionals. Working with industrial compressed air operators to maximise and maintain overall system efficiency, reducing operating costs, ensuring reliability and compliance to relevant standards

Our independence is the key to our success

Huge increases in the cost of energy has seen the company start to focus on energy management. We are now regularly called upon in a consulting capacity to design compressed air systems that are efficient as well as reliable and safe. Our independence is key to our success, we are not encumbered by the constraints of a typical compressor dealer, we design each system with an open mind and scour the market for equipment that best suits our clients needs.

Helpful links : Compressed air system design | New air compressor installations | Compressed air system sales

We use specialist compressed air equipment

The company has invested heavily in specialist instrumentation equipment and the training of personnel to operate and understand measurement and monitoring methods for compressed air and gas systems. Our whole approach sets Compressed Air Technology apart from the crowd, we believe in what we do, are passionate about compressed air and strive to build long lasting, mutually beneficial relationships with a wide range of clients across a variety of sectors.

Helpful links : Air compressor services | Compressed air evaluation & audits | Compressed air leak detection | Compressed air quality testing