Compressed Air Leak Detection and Repair Programs

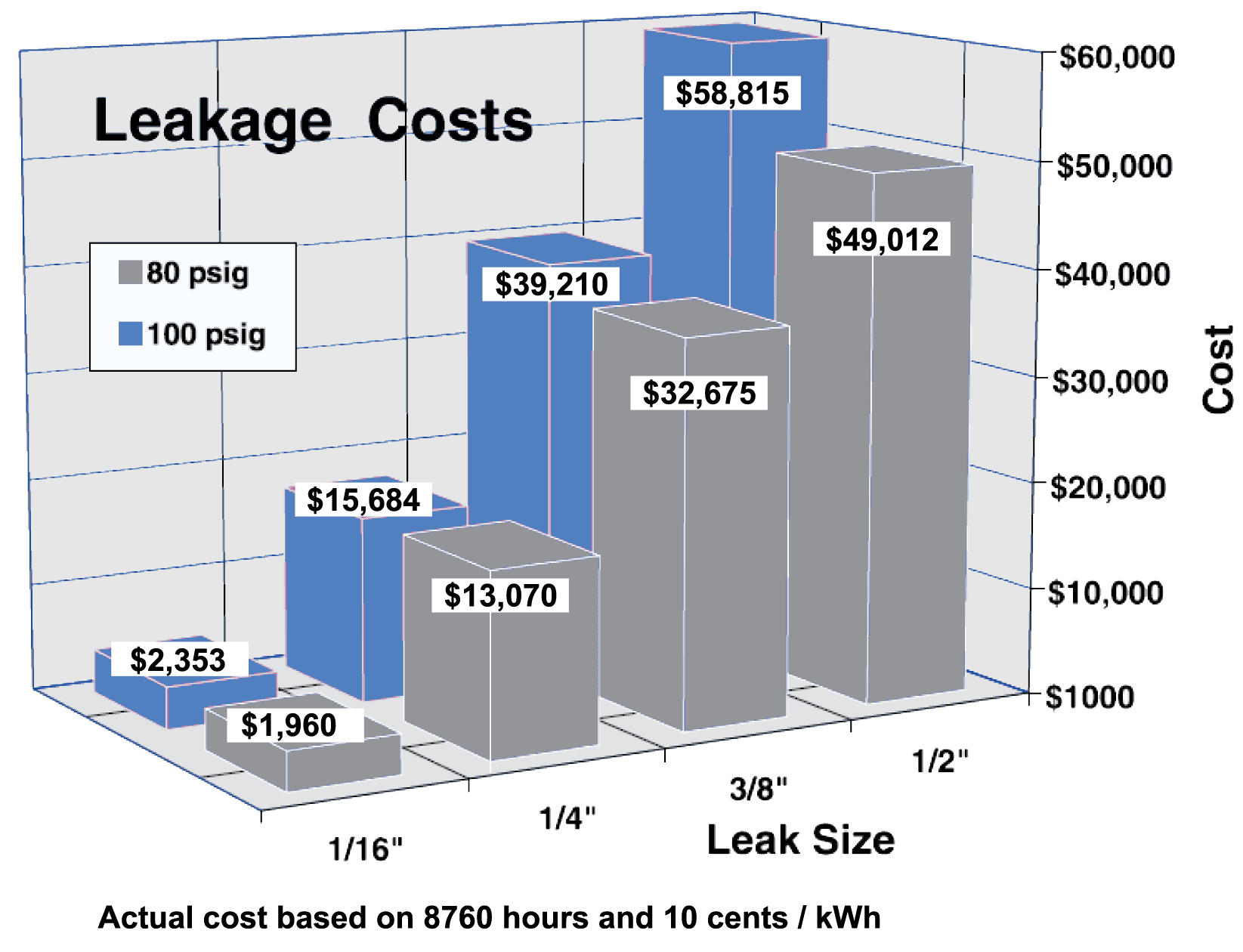

Did you know that most compressed air systems have leaks? Studies show that system leaks typically account for between 20-50% of compressor output, potentially wasting thousands of dollars every year. Most leaks are quick and easy to fix. Ask us how…

Based in Sydney, we service customers Australia-wide.

Facts about industrial air compressor systems

Compressed Air Technology offer a range a leakage detection and repair programs to suit all businesses and budgets. Our state of the art Ultra Sonic Leak Detectors and factory trained technicians are used to detect system leaks, and repairs can often be carried out on the spot, generating instant savings.

Industrial air compressor system leakage decreases significantly at lower pressures. A 20 psi drop in pressure decreases leakage by over 20%.

Compressed Air Leakage Programs

For larger compressed air users or those wishing to take their Leakage Programs to the next level, we offer a more comprehensive approach to ensure leaks are detected, repaired and verified in order to reap the energy saving benefits hidden in your compressed air system

- Measurement – of the non-productive demand, apportioning leakage volumes and evaluating the cost to the business

- Detection – of leaks and recording with tags, photographs and comprehensive reporting

- Grading – of leaks to prioritise repairs and identify potential OH&S issues

- Repair – of leaks or development of in-house repair programs to be undertaken by site personnel

- Verification – of the savings generated after repairs have been completed

Compressed air systems deteriorate over time

A good repair program is a continual repair program. We recommend assessing the level of leakage every 6 months, and actively encourage plant personnel to partake in repair programs, in order to ensure wastage is kept to a minimum.

Remember, every dollar wasted on compressed air leaks is a dollar less on your bottom line – do something about it today by booking an obligation free System Assessment…

MORE INFORMATION

Should you require assistance preventing, monitoring and detecting leaks in your compressed air system, contact us to book an obligation free system assessment.

- Telephone: 1300 663 113

- Email: [email protected]

- Online enquiry form »